Profile of the Instructors

Dr. Dheerendra Kr. Dwivedi completed his B. E. from Government Engineering College, Rewa in 1993 and got Master’s degree from University of Roorkee in 1997, specialization in Welding Engineering. He joined IIT Roorkee as a faculty member in 2004 and presently serving as professor in Department of Mechanical and Industrial Engineering at Indian Institute of Technology, Roorkee, Uttarakhand, India. He has 29 years of experience in research and teaching. He has published 200+ research papers in peer reviewed journals and have 6300 citations . His research interest includes Manufacturing: Welding & Surface Engineering, Mechanical Behaviour, Failure Analysis, Dissimilar Metal Joining, Friction Stir Welding, A-GTAW, Diffusion Bonding, Weldability.

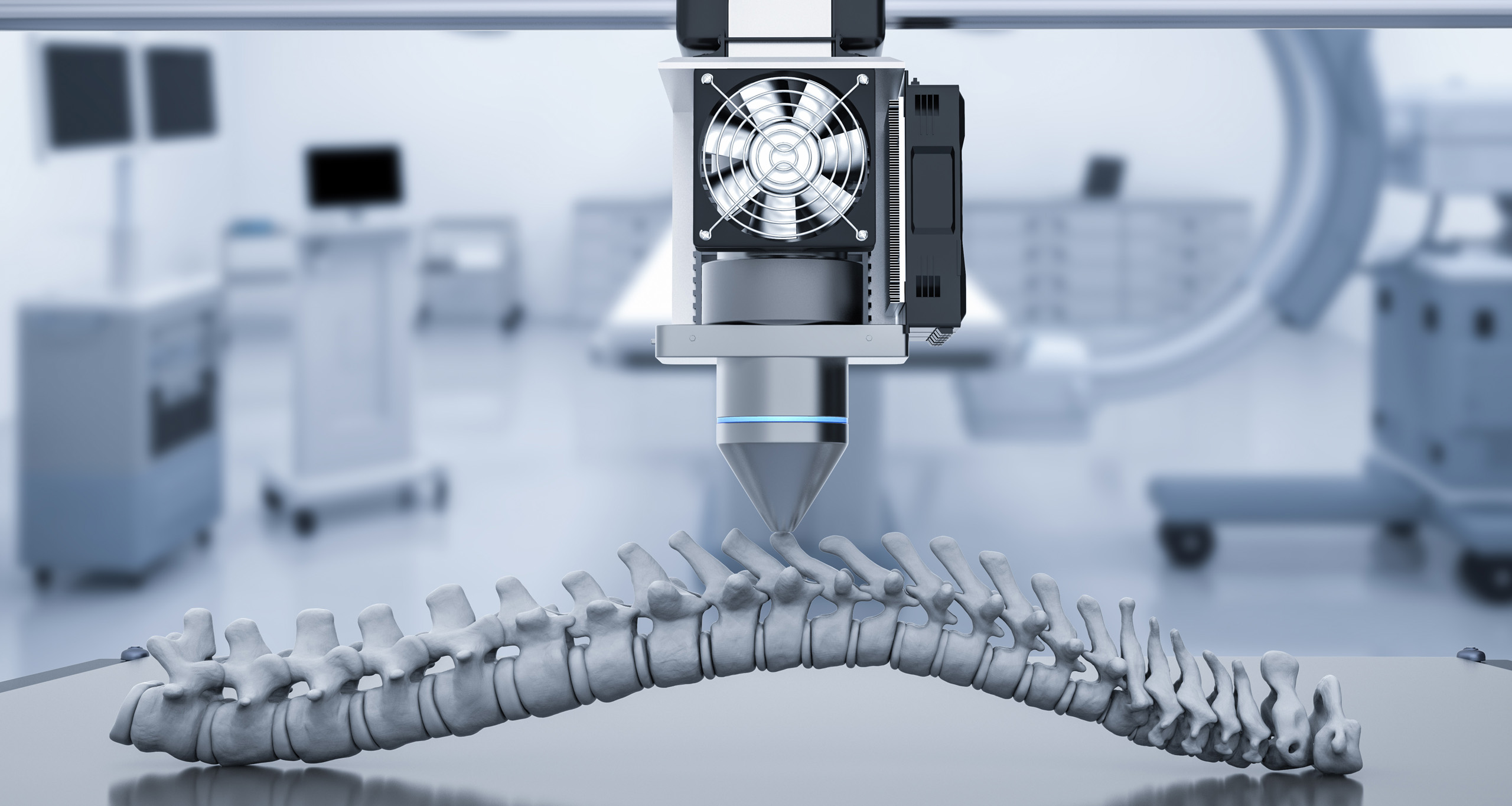

Dr. Varun Sharma completed his B.Tech. degree from Guru Nanak Dev Engineering College in 2011 securing first position and got Master’s degree from Guru Nanak Dev Engineering College in 2013 in Production Engineering specialization. He joined IIT Roorkee as a faculty member in 2018 and presently serving as Associate Professor in Department of Mechanical and Industrial Engineering at Indian Institute of Technology, Roorkee, Uttarakhand, India. He has 8 years of experience in research and teaching. He has published 60 research papers in peer reviewed journals and 15 in national and international conferences. His research interest includes Conventional machining processes, Non-conventional machining processes, Machining and process optimization, Ultrasonic assisted machining, Additive manufacturing/ 3D Printing, Mechanical and biomedical applications.

Reviews

There are no reviews yet.